HOME > PICK UP > Cracking Prevention

CRACKING PREVENTION

Proposals on measures to cracking

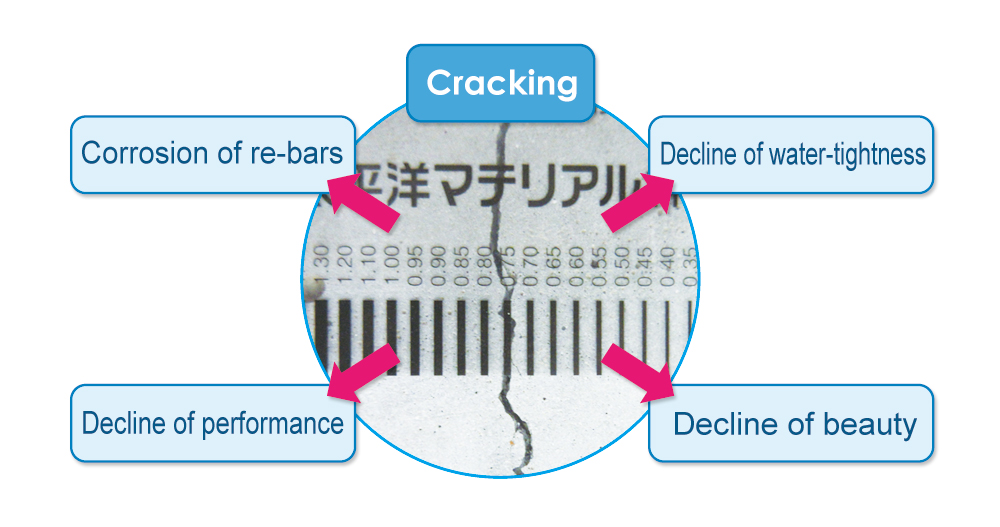

Cracking in concrete occur when the volume shrinkage caused by drying shrinkage, hydration heat, and sudden changes of temperature and humidity is constrained for some reason. Furthermore after construction, cracking will occur due to corrosion of re-bars due to neutralization of concrete, salt damage, etc., and also structural cracks due to earthquakes and land subsidence. These cracking spoil neither aesthetic nor leading to decline of performance, water leakage and finally partial collapse of the structure.

The proposals for measures to cracking is to compensate cracking caused by drying shrinkage or Hydration heat, etc., and these are applied for building concrete structure.

The proposals for measures to cracking is to compensate cracking caused by drying shrinkage or Hydration heat, etc., and these are applied for building concrete structure.

1.The proposal for compensation of cracking on early-stage

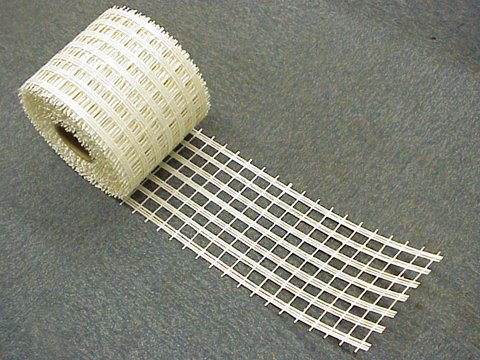

Cracks generated in concrete and mortar will occur in case when stresses generated by the combination of various factors such as temperature, volume change caused by the dissipation of water and the level of restraint at the initial stage when the strength is developed will be higher than Occurs when the tensile strength of hardened structure. The occurrence of cracks can be reduced by attaching or inserting "HYPERNET 60" at the part of reinforced bar or around the openings, corners and top where cracking may occur in advance.

HYPERNET 60

HYPERNET 60

HYPERNET 60

2.The proposal for compensation of cracking caused by drying shrinkage

Dry shrinkage cracking occur due to volume change and restraint caused by the dissipation of water contained in the pores due to the hydration reaction of cement and water. There are two methods to compensate the drying shrinkage cracking; one is to dose and mix an expansive additive or a shrinkage reducing agent into with concrete when it ready-mix concrete is produced, and the other is to apply a shrinkage reducing agent to the surface of the hardened concrete as soon as the concrete form is removed.

Method of dosing when concrete is produced (Ready mixed concrete)

The following expansive additive or shrinkage reducing agent we propose can compensate the deformation of shrinkage, so that the occurrence of cracking caused by drying shrinkage can be reduced.

Expansive additive for concrete

Concrete using HYPER EXPAN-K, an expansive additive for concrete, appropriately expands on the early stage of hardening , and compressive stress is introduced into the concrete by retaining materials such as re-bars, which is called Pre-stress Effect. The tensile stress generated by drying shrinkage of the concrete etc. is cancelled or deceased by the compressive stress according to the Pre-stress, so that the occurrence of cracking is compensated.

As the family of the expansive additives, the following materials are available.

HYPER EXPAN-K : Low Dosage Type

N-EX : High Early Strength Type

EXPAN-S : Standard Type

HYPER EXPAN-K : Low Dosage Type

N-EX : High Early Strength Type

EXPAN-S : Standard Type

Shrinkage Reducing Agent

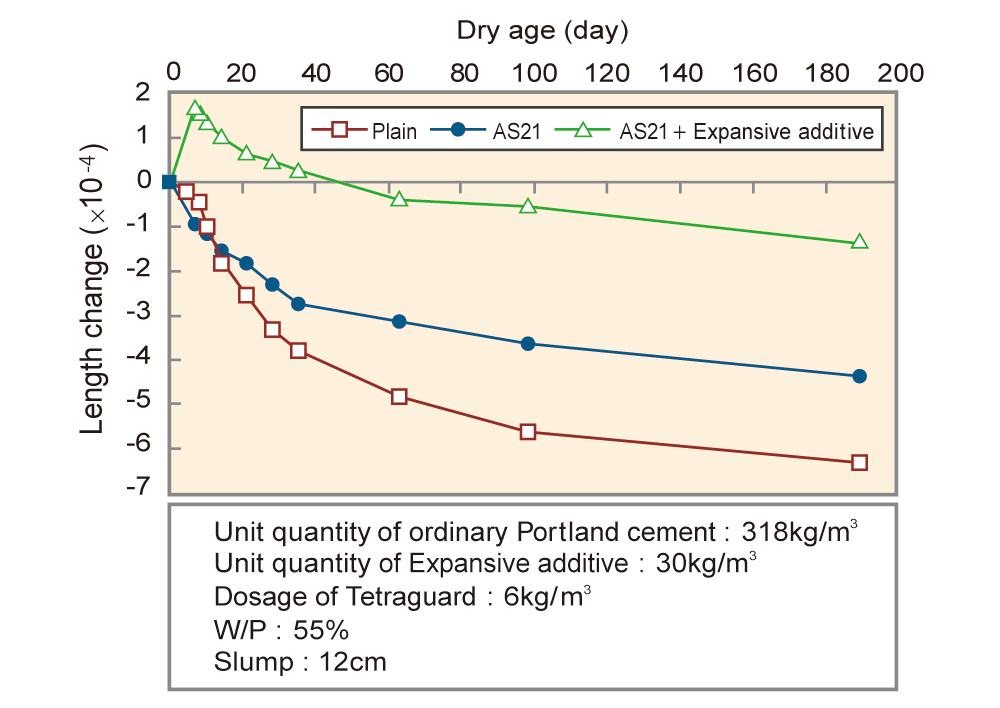

TETRAGUARD, a shrinkage reducing agent, can reduce the drying shrinkage itself according to weakening the tension caused by capillary that is one of main causes of drying shrinkage.

The performance of TETRAGUARD on its Shrinkage Reducing

The Effect of TETRAGUARD

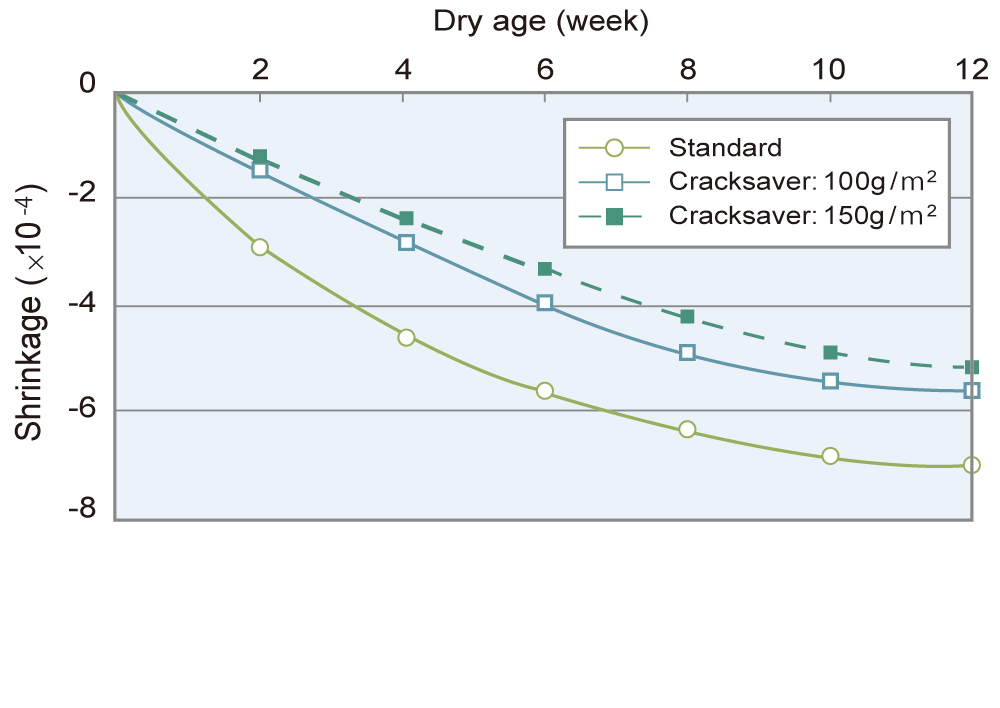

Method of applying a shrinkage reducing agent to the surface of the hardened concrete

By applying CRACKSAVER, a shrinkage reducing agent, to the surface of concrete when the form is removed, the CRACKSAVER penetrates into clink of capillary, reduces the tension of the capillary that is generated by dissipation of water, and finally reduces the drying shrinkage.

3.The proposal on compensation of cracking caused by heat generated by reaction of hydration

Recently, concrete structures are getting larger and the application like huge amount of concrete are rapidly cast so that force stress of heat caused by the reaction of hydration in concrete generates cracking or gives concrete some bad influences which cannot be ignored on the design of concrete. HYPER EXPAN-M(for restraint of hydration heat) can control the generation of the heat caused by the reaction of the hydration on the early stage and can gradually compensate the shrinkage generated at the decrease stage of concrete temperature with its expansion.

4.Autogenous shrinkage cracking

Autogenous shrinkage cracking can be compensated by dosing an expansive additive for concrete or a shrinkage reducing agent to concrete with low ratio of cement quantity, in which the autogenous shrinkage cracking occurs easily.

Expansive additive for concrete : HYPER EXPAN-K, N-EX, EXPAN-S

Shrinkage reducing agent : TETRAGUARD, CRACKSAVER

Shrinkage reducing agent : TETRAGUARD, CRACKSAVER